Our Capabilities

Manufacturing Services

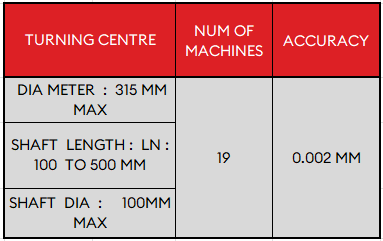

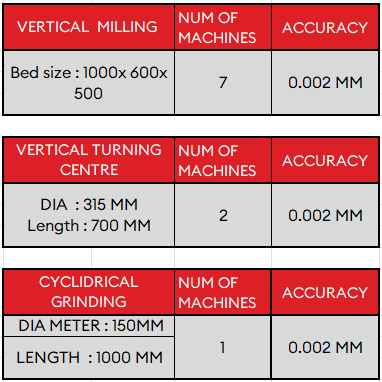

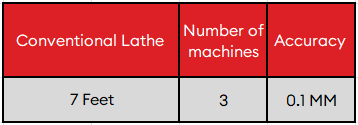

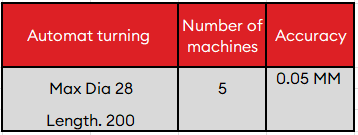

Turning and Milling

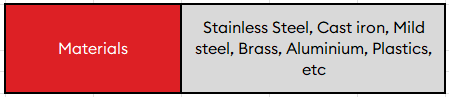

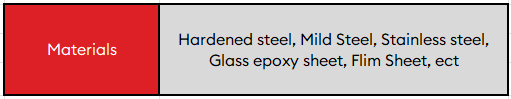

Our “Turning, Milling and Grinding division” as the name suggests specializes is exactly that. We machine a wide range of materials and designs like valves, pump parts, rings, shafts, studs, bolts and more, for different industrial sectors.

More Information ⇩

Sheet-Metal

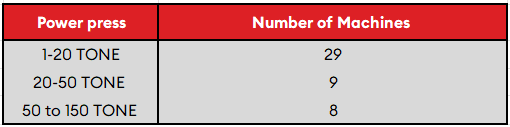

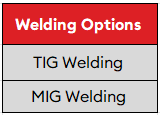

We produce a wide range of products like washers, clamps, hinges, handles, strips, perforated parts, housings, welded parts, and more from a wide range of metals. Tooling is done in-house in our “Tool design and fabrication division”.

More Information ⇩

Forging

Our portfolio includes several components that are forged and finished using our “Turning, milling and grinding division”. We work with our forging partners to manufacture components of different designs and materials.

Casting

Working with our trusted casting partners to provide our customers a wide range of casting and material options. Once casted the product quality is checked and finishing operations are done inhouse in our “Turning, Milling and Grinding division”.

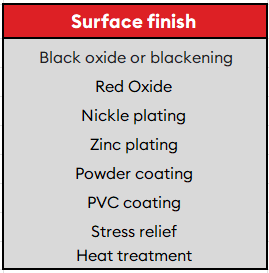

Surface Finish

We do different surface finishes for our products depending on the customer’s requirement.

More Information ⇩

Plastic Moulding

We work with our plastic molding partners to source and assemble a variety of plastic molding parts for several different industrial sectors. We do pneumatic parts, housings, caps, connectors and more

Material buying

Is about finding the balance between the quality of raw materials and affordability. Through our wide network of vendors and contacts in the field we facilitate you to do exactly that- may it be to use in our manufacturing for you or shipping it directly.

Quality Process

- Our team works with you to accommodate special quality requirements in our process, to give you a tailor made Quality plan that is designed based on you business needs.

- Non-disclosure agreements are signed with our partners to protect customers confidentiality.

Quality Reports

The Quality report can be simple to elaborate on depending on the customer’s need.

Standard Report Content

- Quantity of parts shipped matches PO

- Critical dimensions tested

- Set tolerance for dimensions

- Surface finish

- Quantity of samples tested

Other Options

• Material grade

• Material Properties

• Chemical Analysis

• Heat Treatment

• Other special tests repost can be added upon request.